| Sign In | Join Free | My insurersguide.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My insurersguide.com |

|

Brand Name : ShuangYi

Model Number : USB-04M-A16S6A6-000H

Certification : ROHS, HF, ISO 9001, ISO 14001, IATF 16959

Place of Origin : China

MOQ : 1000

Price : $0.05-0.07 PCS FOB

Payment Terms : T/T

Supply Ability : 500000 pcs per month

Delivery Time : 8-15 working days

Packaging Details : Tape and Reel, 1500 per case, 10KG

Solder Cup : Wide solder cup design (reinforced P1 & P4 pads)

Current Rating : 3A max

Contact Resistance : ≤30mΩ

Plating : Black gold-plated terminals (Au over Ni)

Insulation Resistance : ≥500MΩ (500V DC)

Withstand Voltage : 500V AC / 1 minute

Durability : ≥5000 mating cycles

Salt-Spray Test : ≥48 hours

Flammability / Compliance : RoHS2.0 + HF

Operating Temperature : -25°C to +85°C

Mechanical Mating Force : 35N max

Unmating Force : 10N min

Terminal Plating Thickness : Ni base + Au plating on contact & solder area

Product Description

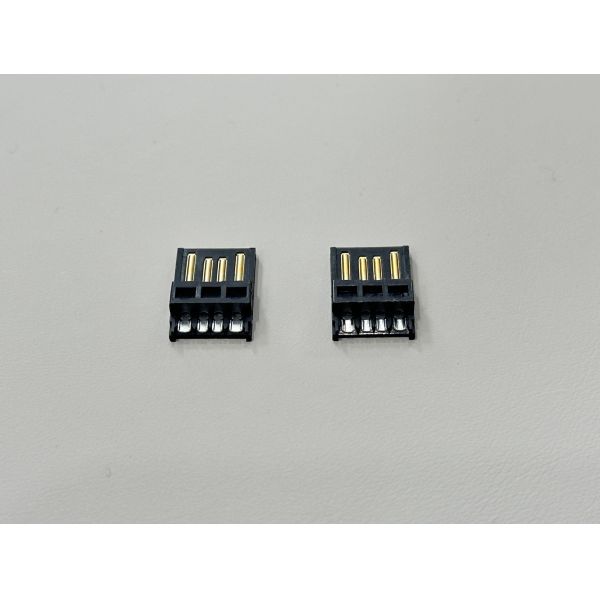

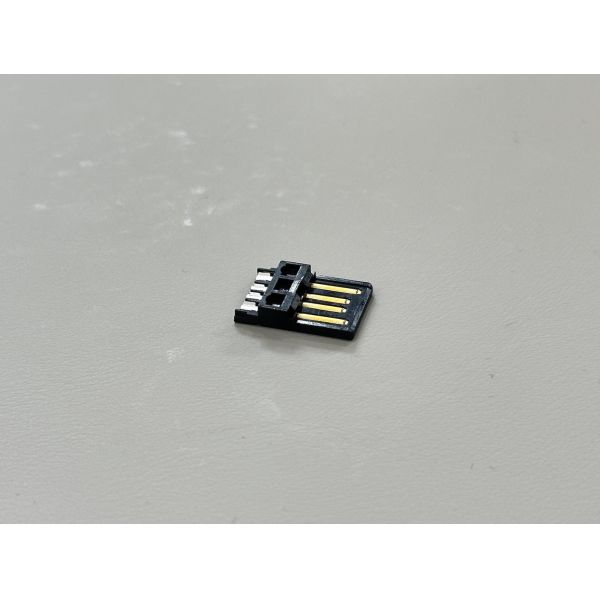

This USB Type-A 4Pin plug terminal connector is designed for electrical and electronic cable assembly, providing a compact solution for both power delivery and high-speed data signal transmission. The connector uses a copper-alloy contact system with thick nickel under-plating and gold-plated terminals to ensure low contact resistance, stable conductivity, and long-term corrosion resistance.

The solder-cup terminals make it easy to attach power and signal wires in custom USB cables, chargers and adapters. A high-temperature black thermoplastic housing withstands lead-free reflow and hand-soldering processes, while the contact geometry is optimized for smooth mating with standard USB Type-A receptacles. With a current rating up to 3 A per pin and durability of 5,000 mating cycles or more, this connector is suitable for demanding PC, server, industrial and automotive electronics environments.

| Connector type | USB Type-A plug terminal connector |

| Function | Power and high-speed data signal transmission |

| Position / pin count | 4 pins |

| Pin style | Solder-cup / solder-crimp terminals for wire termination |

| Contact plating | Approx. 30 μ" gold on contact area, over 50 μ" nickel under-plating |

| Solder area plating | Heavy gold plating on solder & crimp area for reliable electrical connection |

| Rated current | 3 A max per pin at 250 VAC |

| Rated voltage | 250 VAC |

| Contact resistance | ≤ 30 mΩ (initial) |

| Insulation resistance | ≥ 1000 MΩ at 500 VDC |

| Dielectric withstand voltage | 500 VAC / 1 minute between contacts and shell |

| Durability | ≥ 5,000 mating cycles (USB plug/unplug) |

| Mating force | ≤ 35 N |

| Unmating force | ≥ 10 N |

| Housing material | High-temperature thermoplastic, UL94-V0, black |

| Terminal material | High-conductivity copper alloy |

| Wire termination range | Typically AWG 26–22 stranded copper wire (customization available) |

| Operating temperature | −25 °C to +80 °C (reference design range) |

| Environmental compliance | RoHS 2.0 + Halogen-Free |

| Custom options | Wire gauge, cable length, over-molding, color, packaging, OEM/ODM |

Applications

Custom USB data and charging cables for mobile phones, tablets, handheld terminals and consumer electronics

Internal wire-to-board USB jumpers in PCs, servers, routers and storage devices

Industrial control panels and HMI equipment requiring robust USB connectors for configuration or data logging

Automotive infotainment and diagnostic interfaces where reliable power and signal connectors are needed

USB extension, adapter and docking products that require customized cable harnesses or over-molded solutions

Ensure the wire gauge and insulation OD match the solder-cup size to avoid poor wetting or mechanical stress at the terminal.

Observe recommended current and voltage ratings; do not overload the contacts in high-power charging designs.

During soldering, avoid excessive heating time and temperature to prevent housing deformation or loss of spring force in the terminals.

Keep contact surfaces clean; contamination such as flux residue, oil or dust can increase contact resistance and affect signal integrity.

For high-speed data transmission, use twisted-pair, shielded USB cable and maintain controlled impedance from cable to connector.

When used in automotive or industrial environments, consider additional over-molding, strain-relief and shielding to improve vibration resistance and EMC performance.

|

|

High-Precision USB 2.0 AM Connector Wire-Solder Type with Wide Solder Cup, Black Gold-Plated Terminal Connector Images |